Decrypting Vacuum Insulation: Why Do Some Bottles Stay Cold for 24 Hours While Others Fail?

A B2B Buyer’s Guide: The Invisible Craftsmanship from Copper Plating ?

For brand owners and wholesalers, nothing is worse than receiving customer complaints that "this bottle doesn't keep water cold." While almost every stainless steel bottle on the market claims to have "vacuum insulation," the gap in performance can be massive. Some can lock in the chill for 24 hours on a scorching beach, while others turn lukewarm in just four.

As industry experts with 15 years of manufacturing experience, Sunlight Bottle is here to deconstruct the "black technology" inside a high-quality vacuum flask. This isn't just about stainless steel; it's about the microscopic craftsmanship you usually can't see.

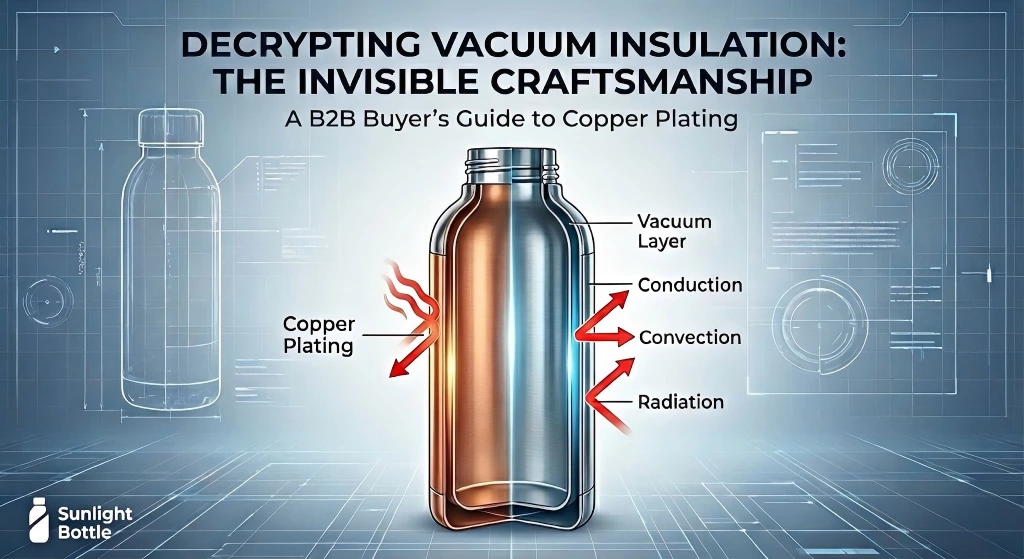

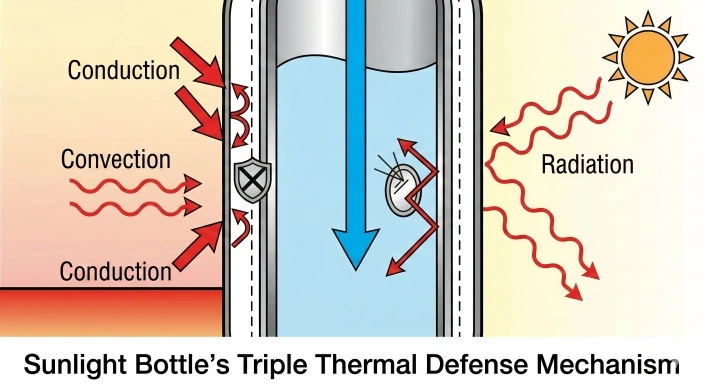

1. The Physics of Heat Transfer: Who Are We Fighting?

To understand insulation, you first need to understand how heat escapes. Thermal energy moves in three ways:

-

Conduction: Heat moves through solid contact (if the bottle wall feels hot to the touch, conduction is happening).

-

Convection: Heat moves through the flow of air or liquid.

-

Radiation: Heat travels as infrared waves (similar to how you feel the sun's warmth).

A standard single-wall bottle cannot stop any of these. A premium vacuum bottle, however, is a precision defense system designed to block all three.

2. The Core Defense: Double-Wall Vacuum Technology

This is the foundation of insulation. We use two layers of stainless steel (an inner liner and an outer shell) and create a "Vacuum Layer" between them.

-

Blocking Conduction & Convection: Since there are no air molecules in a vacuum, heat cannot travel through it via conduction or convection. It is essentially an impassable moat between the liquid and the outside world.

-

Sunlight’s Standard: We pump our vacuum to an extremely high standard and bake the bottles in a 500°C furnace to ensure the vacuum layer is absolutely pure.

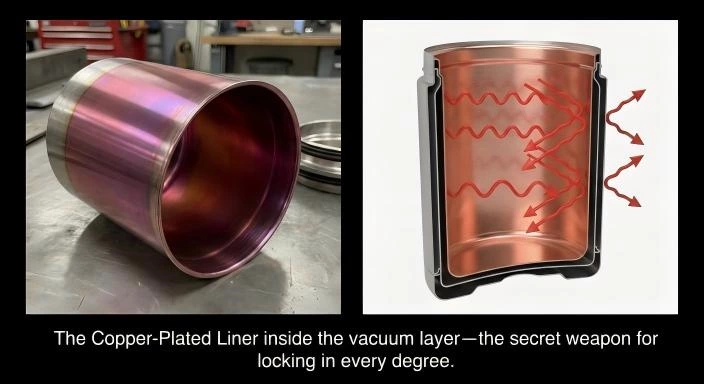

3. The Invisible Champion: Copper Plating

Even with a vacuum layer, heat can still travel through "Radiation" (like sunlight traveling through the vacuum of space). This is why cheap vacuum bottles fail—they can't stop radiative heat transfer.

To solve this, Sunlight Bottle adds a precision Copper Plating step to the outside of the inner liner (inside the vacuum space).

-

Reflecting Infrared: Copper is an excellent reflector of thermal radiation. This invisible copper film acts like a mirror, reflecting heat trying to escape back into the bottle.

-

The Data: Lab tests show that vacuum bottles with a copper plating layer retain temperature 30% better than those without. This is a key detail that distinguishes "High-End OEM Products" from "Commodity Goods."

4. Our 100% Inspection Promise

Theory must be backed by reality. At the Sunlight Bottle factory, every single bottle coming off the line undergoes rigorous thermal testing:

-

Infrared Thermal Scanning: We fill bottles with hot water and pass them through an automated infrared camera. Any bottle showing a "Heat Spot" on the exterior indicates a vacuum failure and is automatically rejected by robotic arms.

-

24-Hour Retention Test: We randomly sample every batch for a full 24-hour test (0°C - 100°C extreme differential) to ensure data compliance.

Conclusion: Choose a Reliable Manufacturer for Your Brand

When you source OEM water bottles, you aren't just buying stainless steel; you are buying thermodynamics engineering. Sunlight Bottle insists on the full process combination: Food-Grade 304/316 Steel + High Vacuum + Copper Plating + Getter.

Want to test our insulation performance yourself?

👉 [Click Here to Contact Us] and we will ship you a free sample featuring our latest copper-plating technology. Let the product speak for itself.